Introduction to Steam-Powered Mills

The industrial landscape of the late 18th and 19th centuries underwent profound changes with the advent of steam power. This development significantly impacted many sectors, none more so than the milling industry, where steam engines replaced traditional water and windmills. This evolution signaled a major shift in industrial technology and operations, effectively laying the groundwork for modern industry.

Development and Implementation

The transition to steam power was propelled by the innovative work of pioneers like James Watt, whose enhancements to the steam engine made it more efficient and applicable across various industries. Unlike water-powered mills that relied on proximity to rivers or windmills dependent on weather, steam-powered mills had the advantage of being relatively independent of geographical constraints. As a result, mills could be established in urban locations, accelerating industrialization and urban growth.

Urban siting meant that mills were closer to a larger workforce and to markets for their products. This contributed substantially to the rise of industrial hubs and the reshaping of economic centers. By decentralizing the dependence on natural energy sources, steam power revolutionized not just where industries were located, but also their scale and scope.

Advantages of Steam Power

The shift to steam power brought distinct advantages over traditional power sources. The most immediate benefit was its consistency and reliability, as it was not subject to the whims of nature. This reliability allowed mills to operate continuously, enhancing production schedules and expanding output. As a result, production speed and efficiency soared, supporting larger-scale operations.

Another key advantage was the flexibility that steam power offered in terms of location. Since mills no longer needed to be near rivers or in windy areas, they could be built in locations chosen for proximity to labor markets and transportation infrastructure rather than energy sources. This flexibility facilitated the agglomeration of industries in burgeoning urban areas, propelling them to become vital industrial centers.

Impact on the Textile Industry

Among the various industries transformed by steam power, the textile industry was perhaps the most dramatically affected. Steam engines powered new, advanced machinery, including the spinning mule and power looms, which significantly increased the scale and efficiency of textile production. The mechanization of textile mills reduced the reliance on manual labor and played a key role in the mass production of textiles.

This industrialization within the textile sector contributed to the growth of the consumer economy by making textiles more affordable and widely available. Furthermore, it ushered in a new era of industrial capitalism, as businesses scaled up operations to meet both domestic and international demand. The labor force also transformed, with many workers migrating from rural areas to urban centers to take advantage of factory jobs, fundamentally altering social and economic structures.

Technological Innovations

The successful integration of steam power into mills was not without its challenges. It spurred numerous technological innovations aimed at refining and maximizing the potential of steam engines and associated machinery. Engineers had to devise more efficient steam engines to ensure that energy usage was optimized. This included improvements to boiler designs and precision in engineering mechanical components.

These innovations not only enhanced productivity but also led to further advancements in engineering and technology. Improved materials and designs permitted mills to become even larger and more efficient, reinforcing the competitive edge that steam-powered operations had over their predecessors. The ripple effect of these enhancements extended beyond the milling industry, influencing developments in transportation and other industrial sectors.

Environmental and Societal Impacts

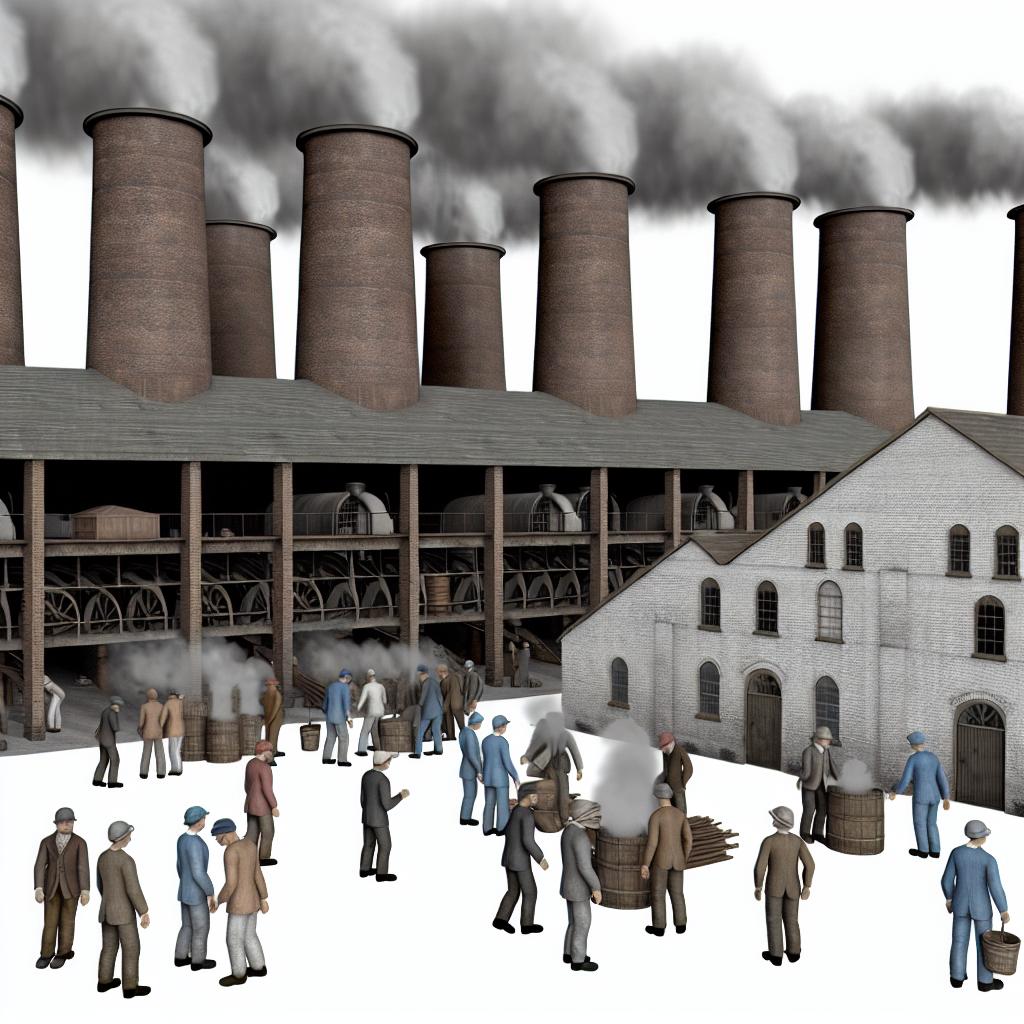

However, the industrial progress brought by steam-powered mills was a double-edged sword, having significant environmental and societal implications. The reliance on coal to fuel steam engines contributed to increased air pollution, which was a major concern for the burgeoning urban environments now hosting these mills. The smoke from burning coal was a visible reminder of the environmental cost of industrialization.

Moreover, the concentration of mills and other factories in urban areas led to overcrowded, unhealthy living and working conditions. Many workers lived in impoverished neighborhoods with inadequate sanitation, and they faced long working hours under often harsh conditions. This inequality and hardship contributed to various social movements that would later advocate for labor rights and better working conditions.

Conclusion

In summary, steam-powered mills were instrumental in advancing industrial society, facilitating increased productivity and efficiency. They marked a decisive turning point in industrial history by breaking the link between production capabilities and natural energy sources. While not without environmental and social challenges, the revolution brought about by steam power played a pivotal role in shaping the modern industrial landscape. To delve deeper into the history and technical aspects of steam-powered mills, one might consider exploring resources from historical archives or specialized industrial history websites.